On the market since 2015

Yearly more than 6 mil m2 of lamellas dried on DryWoodMesh®

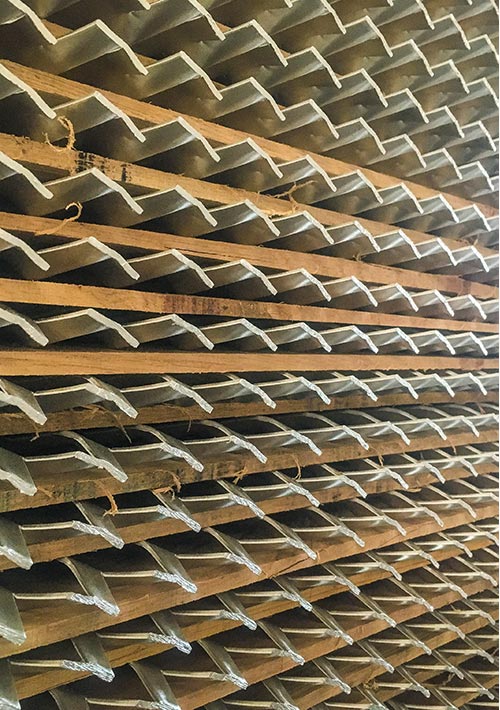

What Is DryWoodMesh®

And How It Works

DryWoodMesh® is specifically shaped aluminium sheet developed by Czech company Technotron-Metal s.r.o. We offer several options and types according to customer needs. Specially shaped meshes are used for interlacing the layers of wooden lamellas in the drying kiln. The DryWoodMesh® replaces the wooden bars and brings many advantages thanks to controlled air flow in the kiln.

DryWoodMesh® Features

Stresses are induced trying to force moisture out from the center of the thicker lumber.

With DryWoodMesh® you can cut your wood approximately to the final thickness of the wooden lamellas prior to kiln drying.

Drying thinner wood lamellas results in less induced stresses and provides more uniform moisture content gradients during the kiln drying proces.

6 mil. m2 of dried lamellas are produced globally every year on special meshes

Free trial – 60 DryWoodMesh® pieces

Free of charge

Get ahead of your competitors – DryWoodMesh® is future technology available today!

8 years of experience

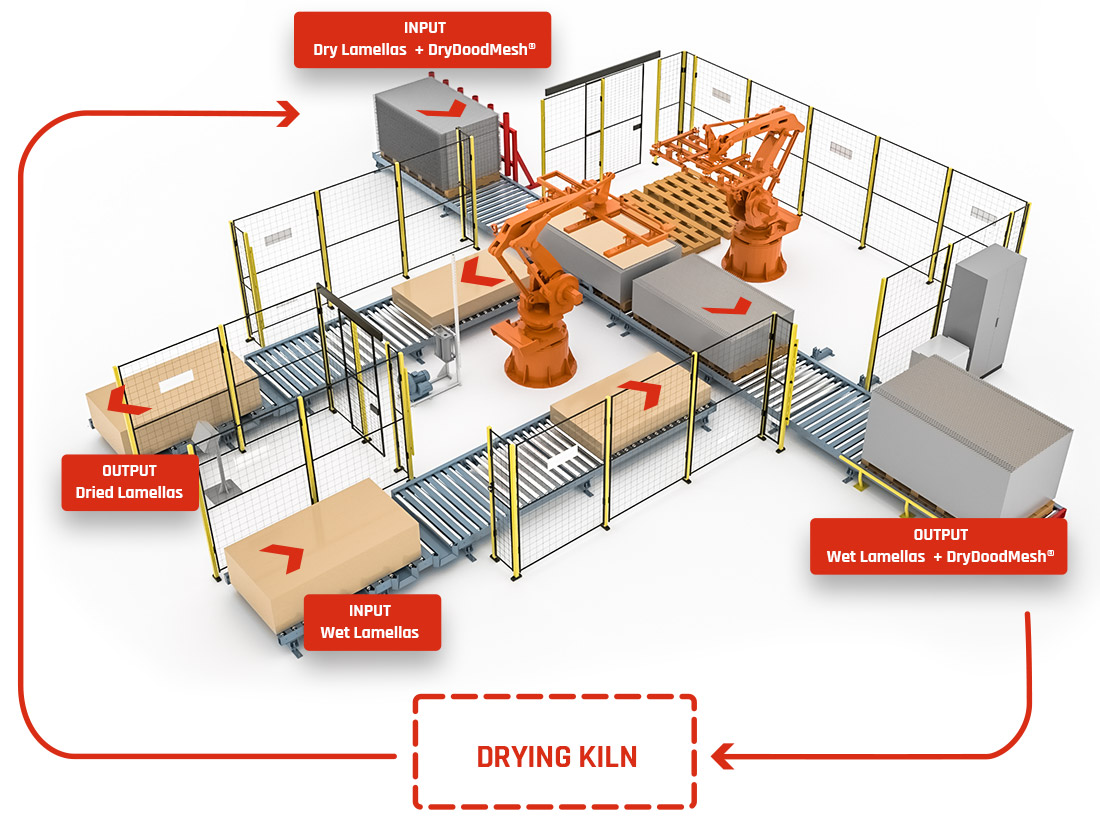

Automatic palletizing of DryWoodMesh® and Wooden Lamellas

Using DryWoodMesh® is a great way to increase the efficiency of your drying process.

Introducing DryWoodMesh® to your facility can be used also as an impulse for automation of manipulation

the wood and the interlacing DryWoodMesh®.

At the turn of the year 2016/2017 the first robotic workspace was installed for the significant European wood floor producer. Next workplaces are being installed and others are in the pipeline. The standard solution can be adjusted for every wood producer’s need according to the requested capacity, type of material, available space etc.

Manipulation with wood is historically well mastered discipline of automation, even it is not the easiest automation task due to the wood natural not-exact shape. The more special issue is manipulation with DryWoodMesh®. The DryWoodMesh® is made of aluminium, therefore magnetic grippers cannot be used. It is also sophisticatedly shaped according to airflow simulations, what prevents it from being lifted by standard suction or mechanical grippers.

Thanks to the close cooperation between the DryWoodMesh® producer and Ingeteam, a specific gripper was developed. This gripper allows manipulating DryWoodMesh® gently, reliably and quickly.

If your factory is using wooden sticks for interlacing the lamellas, the robotic workplace can be delivered with a gripper designed to manipulate the wooden sticks or also with an universal gripper allowing manipulation with both DryWoodMesh® and wooden sticks.

The application process comprises:

Workplace design according to customer’s specification (manipulation capacity, available space, wooden lamellas dimensions etc.)

Technical study, basic engineering, detail engineering, delivery, installation, commissioning

Automation of the manufacturing process in relation to other workplaces of the production facility

Robotic Manipulation With DryWoodMesh® Simulation

Robotic Manipulation With DryWoodMesh® in Action

Process development and Technical Support

Coordination of DryWoodMesh® tests

in cooperative research centres

Ingeteam a.s. (robotics)

MMV Ostrava (computer modeling)

VÚHŽ Dobrá Frydek-Místek, Czech Republic

(physical laboratory trials)

Fagus Komárno Slovakia (trials of drying cycles with DryWoodMesh® and customers´s lamellas)

Assistance during DryWoodMesh® trials

Contact Us

DryWoodMesh® Testing Centre: Fagus, spol.s.r.o.

Rolnickej skoly 1519

945 01 Komárno

Slovak Republic

DryWoodMesh® / Production and Sales

Technotron-Metal s.r.o.

Příborská 1494

738 01 Frýdek-Místek

Czech Republic

Radim Zdarsa / Technotron-Metal s.r.o.

West European Customers

Ladislav Juhos

Head of DryWoodMesh®

Research and Testing Centre

Piotr Kicuła

DryWoodMesh® Specialist Sales

Poland, Germany